Vastu For Home

Home is our identity. An excellent House is an alliance of rooms with precisely defined entry and exit point.

In this article we are discussing on what vastu is? And why should we follow vastu?

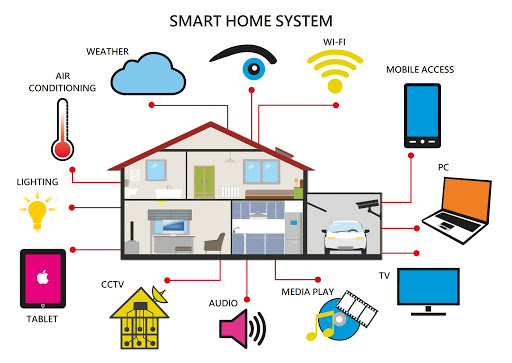

The meaning of vastu is dwelling, which is the home for god and humans. Vastu shastra depends on different energies that originates from atmosphere like solar energy from sun, cosmic energy, lunar energy, thermal energy, magnetic energy, light energy, wind energy.

These energies can be adjusted to upgrade peace, prosperity and achievements. Vastu is important in such a way that if a house is made according to these principles, the inmates enjoy all the happiness in life and for a well-balanced life.

It’s a fact to say that buildings and even the land on which a building is erected has vibrations of energy associated with it. Some energies are positive (with pleasing effects) while others are negative (having terrible effects) on us. What Vastu does?

Vastu targets to eliminate negative and enhance positive energy present at a place or location so that a person, family or even business inhabiting a building become prosperous and progressive. Besides, vastu principles encourage all divine powers to increase one’s positive thinking and progressive actions.

I guess all are now clear about vastu. Now, can anyone tell how did it originates? What’s your take on vastu? What do you want to know about vastu? Leave comment.

Stay tuned for further updates about vastu…

………………………………………………………………………………………………………………………………….

Like us on Facebook :- https://www.facebook.com/SanghiCement

Follow us on Linkedin :- https://www.linkedin.com/company/sanghi-industries-ltd

Subscribe us on Youtube :- https://www.youtube.com/SanghiIndustries-Ltd

For any Inquiry visit :- http://www.sanghicement.com/inquiry-form

Contact us on Whatsapp :- +91-79-26838000